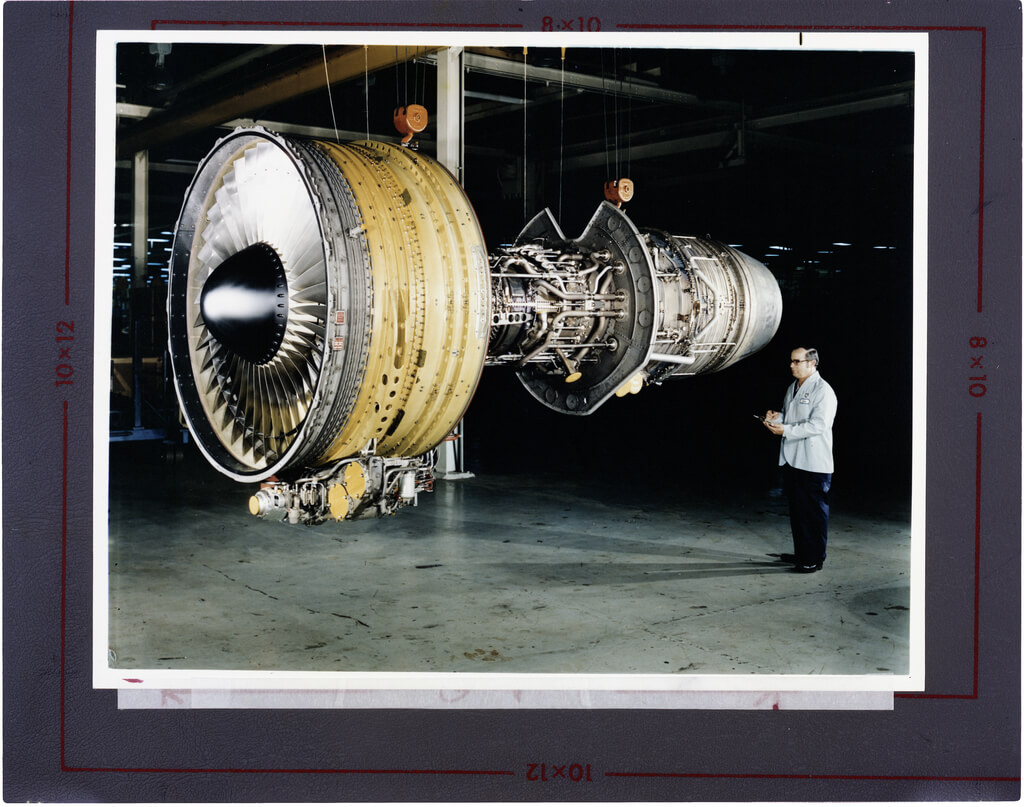

Discover the remarkable CF6 engine, a masterpiece of aviation engineering that has revolutionized commercial flight. With over 8,500 units produced, this turbofan engine series continues to set industry standards for performance, reliability, and environmental responsibility. Let’s explore what makes this powerhouse of aviation so exceptional.

The CF6 engine, developed by GE Aviation, represents the pinnacle of turbofan engine technology in commercial aerospace. Its innovative modular design allows for easy maintenance and component interchangeability, while delivering exceptional performance through advanced aerodynamics and high efficiency.

Discover the reliable CF6-80 by National Aero Stands, designed for secure transportation and storage of engines.

History and Development of the CF6 Engine

The CF6’s journey began in September 1967 when GE Aviation initiated its development. A significant milestone occurred in April 1968 when the CF6-6 was chosen to power the McDonnell Douglas DC-10 Series 10 aircraft, marking GE’s entry into commercial aviation.

- CF6-6 – Original model

- CF6-50 – Enhanced performance variant

- CF6-80A – Advanced technology integration

- CF6-80C2 – Improved efficiency model

- CF6-80E1 – Latest generation with enhanced capabilities

Key Specifications of the CF6 Engine

| Specification | Value |

|---|---|

| Fan Diameter | 86.4 inches |

| Airflow | 1,300 lb/s |

| Bypass Ratio | 5.72 |

| Overall Pressure Ratio | 24.3 |

| Maximum Take-off Thrust | 41,500 lb |

| Weight | 3,379 kg (7,450 lb) |

Performance and Efficiency of the CF6 Engine

The CF6 family has evolved significantly, with modern variants like the CF6-80E delivering up to 70,000 lbs. of thrust – nearly double the original CF6-6 model’s output. This remarkable advancement demonstrates the engine’s continuous technological evolution.

Fuel Efficiency and Environmental Impact

Modern CF6 engines achieve up to 15% better fuel efficiency compared to earlier models. The high bypass design, particularly in the CF6-80C2, delivers the lowest fuel burn in its thrust class, contributing significantly to reduced emissions and environmental sustainability.

Reliability and Maintenance of the CF6 Engine

- Industry-leading reliability ratings

- Specialized maintenance facilities worldwide

- Triple the flights between overhauls compared to earlier versions

- Reduced maintenance costs through innovative design

- Expert care through dedicated service networks

Aircraft Compatibility and Applications

The CF6 engine’s versatility has made it a preferred choice for various aircraft types, from commercial airliners to military transport planes. Its scalable performance and robust design continue to meet diverse aviation needs, powering both twin-engine aircraft and large four-engine jumbo jets with remarkable efficiency.

Commercial Aircraft Using the CF6 Engine

The CF6 engine has established itself as a cornerstone of commercial aviation, powering an extensive range of wide-body aircraft. Its versatility spans across multiple manufacturers and aircraft types.

- Boeing Aircraft – 747, 767 series

- McDonnell Douglas – DC-10, MD-11

- Airbus Aircraft – A300, A310, A330 series

| Engine Variant | Thrust Rating | Aircraft Application |

|---|---|---|

| CF6-80C2B1 | 56,700 lbs | Boeing 747-200/300 |

| CF6-80C2B2 | 52,500 lbs | Boeing 767-200ER/300ER |

Military and Cargo Applications

The CF6 engine’s capabilities extend well beyond commercial passenger aviation, proving its worth in military and cargo operations. In military service, the engine operates as the F138, specifically modified for the U.S. Air Force’s C-5M Super Galaxy strategic airlifter.

In cargo aviation, the CF6 powers several prominent freighter aircraft:

- Boeing 747 Freighter

- McDonnell Douglas MD-11 Freighter

- Military transport variants

Future Prospects and Innovations

The CF6 engine continues to demonstrate strong growth potential in the aviation sector. Industry experts, including Aviation Week & Space Technology’s Guy Norris, project an increase in CF6 production from 50 to 60-80 engines annually by 2020, driven by rising air cargo demand and ongoing Airbus A330 deliveries.

This growth trajectory reflects the CF6’s ability to adapt to evolving industry demands while maintaining its core reliability. The engine’s continuous improvement and innovation make it particularly well-positioned to address future aviation challenges, especially in areas of sustainability and operational efficiency.

Discover the reliable CF6-80E1 by National Aero Stands, designed for secure transportation and storage of engines.

Technological Advancements in the CF6 Engine

- Advanced cooling techniques for improved efficiency

- Sophisticated clearance control systems

- Aerodynamic modifications to blades and vanes

- Integration of advanced materials

- 3-D aero compressor technology

- Modern control systems for enhanced performance

Sustainability and the Future of Aviation

GE Aviation’s commitment to sustainability is reshaping the CF6 engine’s evolution. Current development efforts focus on:

- Enhanced fuel efficiency systems

- Reduced emissions technology

- Compatibility with sustainable aviation fuels (SAFs)

- Noise reduction innovations

- Environmental compliance improvements

As the aviation industry transitions toward greener operations, the CF6 engine’s adaptability to new environmental standards and eco-friendly technologies positions it as a key player in sustainable aviation’s future.

Main Photo: Hunini, CC BY-SA 4.0 httpscreativecommons.orglicensesby-sa4.0, via Wikimedia Commons